- Home

- >

- Products

- >

- Aging Test

- >

- LXPT-150 Yellowing resistance test chamber

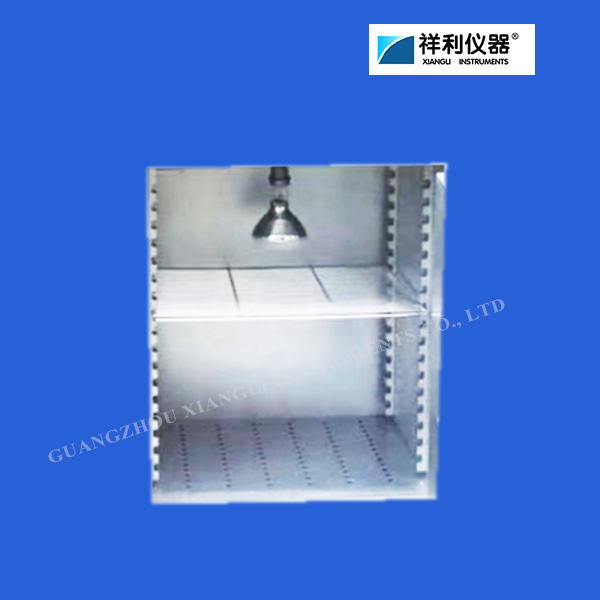

LXPT-150 Yellowing resistance test chamber

Brand :XIANGLI

Product origin :CHINA

Delivery time :7 days

Supply capacity :1000

The machine is used to observe the degree of yellow -resistant changes in the sample. It can be used as a reference with stain -stained gray labels to determine the level of its yellow change.

During the use of the product, during the use of sun radiation or transportation, the color change of the container environment caused the flaws of the product.

Product specification

★ This test chamber is manufactured in accordance with ASTM D1148. The yellowing resistance irradiation test chamber is suitable for simulating the ultraviolet radiation and heat of sunlight.

★ The sample is exposed to ultraviolet irradiation and temperature in the machine. After a period of time, the degree of yellowing resistance of the sample is observed.

★ The stained gray mark can be used as a reference to determine the level of yellowing. The color change of the product due to sunlight radiation during use or the influence of the container environment during transportation will cause defects in the product.

Product parameter

| Inner box size | 600×500×750 mm (W×D×H) |

| Outer box size | about 950×600×1200 mm (W×D×H) |

| Temperature range | Normal temperature +5℃~70℃ |

| Control method | P.I.D. Automatic temperature calculation |

| Temperature analysis | 0.1℃ unit display |

| Control accuracy | ±1℃ |

| Distribution accuracy | ±1%(1℃) at-room80℃ |

| Timer | 0~999.9 hours (minutes) electronic display, power failure memory type, buzzer |

| Storage turntable | Diameter 300mm |

| UV light source | Lamp type, 300W, 1 piece |

| Heating method | Hot air internal circulation |

| Safety protection | Independent EGO over-temperature power-off, safety overload switch |

| Manufacturing material | Internal high-quality steel plate |

| Machine weight | 60kg |

| Power supply | 1PH, AC220V, 10A |

Maintain

1. Open the machines everyday periodically.

2. Operated by the specialist.

3. The equipment and accessories must be deposit in the dry environment.

4. After testing the accessories should be added wiping grease rust, and remove the rust great before test.

5. When the test finished, the power should be closed to avoid any accident.

Certificate