- Home

- >

- Products

- >

- Softening Point Test

- >

- Thermal deformation testing machine

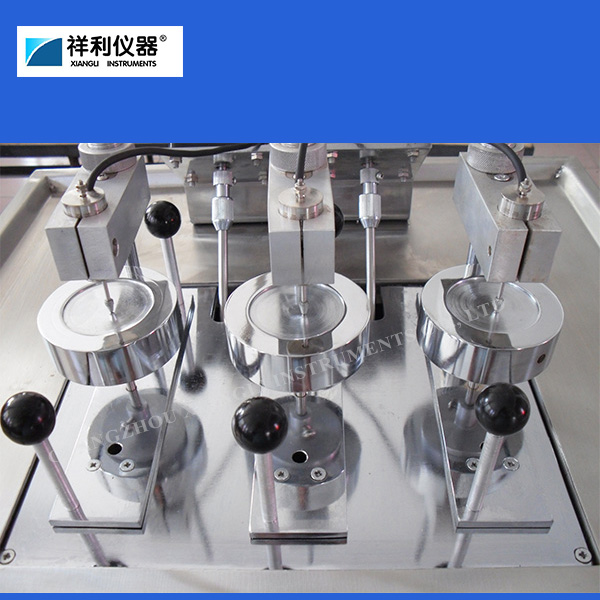

Thermal deformation testing machine

Brand :XIANGLI

Product origin :China

Delivery time :10 days

Supply capacity :1000

XRW-300UB thermal deformation and Vicat softening point measuring instrument uses a PLC programmable controller for temperature adjustment and a touch screen display operation.

Thermal deformation testing machine is simple to operate, easy to use, has stable performance and high product precision.

HTD& Vicat can monitor the test temperature and deformation in real time during the test process.

At the end of the HTD& Vicat test, the system automatically stops heating and can display the test curve.

Product specification

▄The XRW-300UB thermal deformation and Vicat softening point measuring instrument uses a PLC programmable controller for temperature adjustment and a touch screen display operation.

▄This product is simple to operate, easy to use, has stable performance and high product precision.

▄ It can monitor the test temperature and deformation in real time during the test process.

▄ At the end of the test, the system automatically stops heating and can display the test curve.

▄ This series of models is an essential instrument for self-inspection of various quality inspection units, colleges and universities and various enterprises.

Application scope

▄ This machine is mainly used to measure the heat deformation temperature and Vicat softening point temperature of non-metallic materials such as plastics, rubber, nylon, and electrical insulation materials. The products comply with standards such as IS075(E), IS0306(E), GB/T8802, GB/T1633, and GB/T1634.

▄ Model XRW-300UB has a specimen rack lifting function, which can raise or lower the specimen rack at the beginning or end of the test.

Product parameter

▄ Temperature control range: ambient temperature-300℃

▄ Heating rate: (120±10)℃/h (12±1)℃/6min

(50±5)℃/h (5±0.5)℃/6min

▄ Temperature indication error: 0.1℃

▄ Temperature control accuracy: ±0.5℃

▄ Maximum deformation indication error: ±0.001mm,

▄ Deformation measurement range: 0-1.5mm

▄ Number of experimental racks: 3

▄ Load bar and pallet mass: 68g

▄ Heating power: 4kw

▄ Cooling method: natural cooling above 150°C, water cooling or natural cooling below 150°C.

Heating medium: methyl silicone oil (generally choose 200 centistokes for kinematic viscosity) or transformer oil.

Maintain

1. Open the machines everyday periodically.

2. Operated by the specialist.

3. Thermal deformation testing machine and accessories must be deposit in the dry environment.

4. After testing the accessories should be added wiping grease rust, and remove the rust great before test.

5. When the test finished, the power should be closed to avoid any accident.

Certificate