- Home

- >

- Products

- >

- Universal Testing Machine

- >

- Microcomputer control Ring steelness testing machine

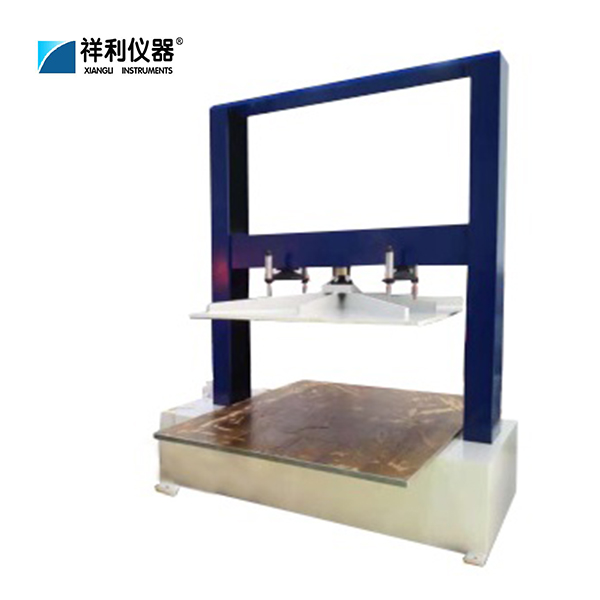

Microcomputer control Ring steelness testing machine

Brand :XIANGLI

Product origin :CHINA

Delivery time :GUANGZHOU

Supply capacity :1000

Applicable to plastic pipe ring softness, ring stiffness, flatness, weld stretch, pipe creep ratio and other tests.

Model: XLS-50HG

Main function of the device

XLS-50HG series Microcomputer control Ring steelness testing machine adopts mechanical loading, electronic measurement, digital continuous speed regulation, and computer real-time control .

The machine simultaneously displays the test force, displacement/speed digitally, and has the test force peak hold function.

Applicable to plastic pipe ring softness, ring stiffness, flatness, weld stretch, pipe creep ratio and other tests. It is an ideal testing equipment for industrial and mining enterprises, research institutes, universities, commodity inspection and arbitration, and technical supervision.

Working principle

The ring stiffness is determined by the force value and deformation value that measured when the pipe is deformed at a constant speed.

The tube sample was placed horizontally, the compression speed of the plate was determined according to the diameter of the tube, and the sample was applied with pressure perpendicular to the two parallel plates.

The reaction force is generated during the deformation, and the ring stiffness is calculated by the force value when the tube sample has a deformation amount of 0.03 di in the diameter direction.

Experiments can be carried out according to GB, ASTM, DIN, ISO, JIS, BS and other standards.

Such as GB/T 9647-2015, GB/T 18477-2001,GB/T 16800-1997, GB/T1947,GB/T 165-2002,GB/T 838-1998, GB/T16491,GB/T5836 standard.

For structural wall tubes with spiral ribs, corrugations or other regular structures (special instructions are required to determine the span of the test machine), the length of the specimen shall be equal to (d i ± 20 mm, but not less than 290 mm, nor greater than 1000 mm)

Test machine manufacturing standard: GB/T 16491-2008 electronic universal testing machine

The main technical parameters

| No. | Item Name | Technical Specifications |

| 1 | Maximum test force | 50KN (additional sensor can be added to extend the force range) |

| 2 | Accuracy level | 0.5 |

| 3 | Test force measurement range | 1%~100%FS (full scale) |

| 4 | Test force indication error | within 0.5% of the indicated value |

| 5 | Test force resolution | The maximum test force is ±1/300000, and the whole process resolution is unchanged. |

| 6 | Ddeformation measurement range | 2% ~ 100% FS |

| 7 | Deformation indication error | ±0.5% of the indicated value |

| 8 | Deformation resolution | 1/300000/maximum up to 1/500000 |

| 9 | Displacement indication error | ±0.5% of the indicated value |

| 10 | Displacement resolution | 0.001mm |

| 11 | Force control rate adjustment range | 0.005~5%FS/s |

| 12 | Force control rate control accuracy | When the rate is <0.05% FS/s, it is ±2% of the set value. When the rate is ≥0.05%FS/s, it is ±0.5% of the set value. |

| 13 | Deformation rate adjustment range | 0.005~5%FS/s |

| 14 | Deformation rate control accuracy | When the rate is <0.05% FS/s, it is within ±2% of the set value. When the rate is ≥0.05%FS/s, it is within ±0.5% of the set value. |

| 15 | Displacement rate adjustment range | 0.01~500mm/min |

| 16 | Displacement rate control accuracy | When the rate is <0.5mm/min, it is ±1% of the set value. When the rate is ≥0.5mm/min, it is ±0.2% of the set value. |

| 17 | Host test space | Down space compression (single space) |

| 18 | Effective stroke | 1800mm (between two pressure plates) |

| 19 | Effective test width | 1200mm |

| 20 | Mainframe dimensions | about 1700*1100*2950 (custom size available) |

| 21 | Host weight | about 1500Kg |

| 22 | Power supply | 220V, 50Hz, 0.75kW |