- Home

- >

- Products

- >

- Softening Point Test

- >

- HTD and vicat softening point temperature instrument

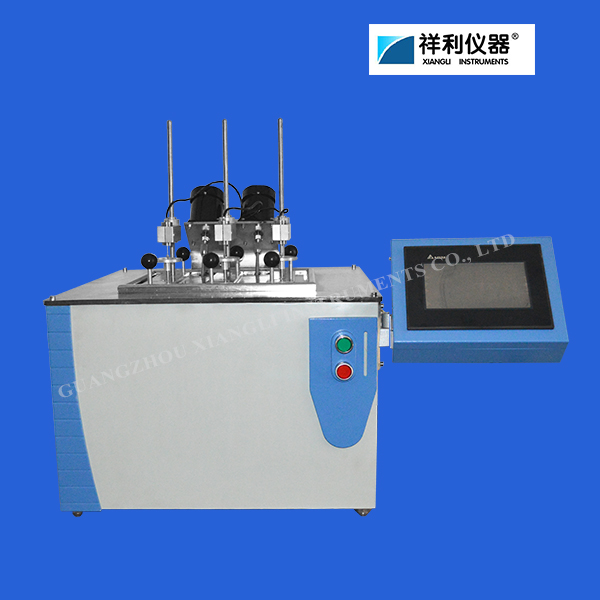

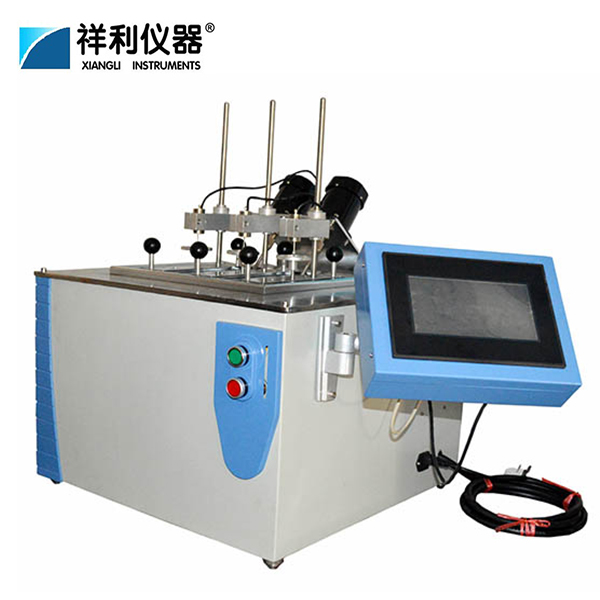

HTD and vicat softening point temperature instrument

Brand :XIANGLI

Product origin :China

Delivery time :10 days

Supply capacity :1000

This product is simple to operate, easy to use, has stable performance and high product precision. It is an essential instrument for self-inspection of various quality inspection units, colleges and universities and various enterprises.

Application

The XRW-300A series thermal deformation and Vicat softening point measuring instrument adopts PLC module control and touch screen display operation (Chinese and English operation interface conversion).

This machine has upper temperature limit protection and automatic shutdown function after the experiment, which can monitor the test temperature and deformation in real time. quantity, and draw the temperature-displacement deformation curve in real time.

Product advantage

▅ This machine has a test data query function and is equipped with a printer (Note: This machine is equipped with a printer that supports photo printing mode and USB interface) and can print test reports and test curves.

▄ This machine is mainly used to measure the heat deformation temperature and Vicat softening point temperature of non-metallic materials such as plastics, rubber, nylon, and electrical insulation materials. The products comply with standards such as IS075(E), IS0306(E), GB/T8802, GB/T1633, and GB/T1634.

Product parameter

1) Temperature control range: ambient temperature-300℃

2) Heating rate: (120±10)℃/h (12±1)℃/6min

(50±5)℃/h (5±0.5)℃/6min

3) Temperature error: ±0.5℃

4) Deformation indication accuracy: 0.001mm,

5) Deformation measurement range: 0-1.5mm

6) Number of sample racks: 3

7) Load rod and pallet mass: 68g

8) Heating medium: methyl silicone oil (choose a viscosity of 200 centistokes) or transformer oil

9) Cooling method: natural cooling above 150℃, water cooling or natural cooling below 150℃.

10) Heating power: 4kw

Working principle

▅ Vicat softening point temperature of thermoplastic plastics: When the temperature rises at a constant speed, the temperature when the standard indenter penetrates the upper surface of the thermoplastic plastic sample to a depth of 1mm under the load conditions specified in the standard.

▅ Thermal deformation temperature of plastic bending load: When the temperature rises at a constant speed, measure the temperature at which the thermoplastic plastic sample is pressed by a standard indenter under the load conditions specified in the standard so that the upper surface of the sample bends and deforms to the specified deflection.

Working conditions

1) Ambient temperature: room temperature

2) The relative humidity of the environment is within 30%-80%.

3) In an environment with no vibration or corrosive media around.

4) The instrument should be installed on a stable workbench.

5) There is no strong magnetic interference in the working environment and no strong convection in the surrounding air.

6). Power supply: AC220V±10%, 50Hz

Maintain

1. Open the machines everyday periodically.

2. Operated by the specialist.

3. HTD and vicat softening point temperature instrument and accessories must be deposit in the dry environment.

4. After testing the accessories should be added wiping grease rust, and remove the rust great before test.

5. When the test finished, the power should be closed to avoid any accident.

Certificate