- Home

- >

- Products

- >

- Universal Testing Machine

- >

- WXL-H50 Microcomputer controlled electronic ring stiffness testing machine

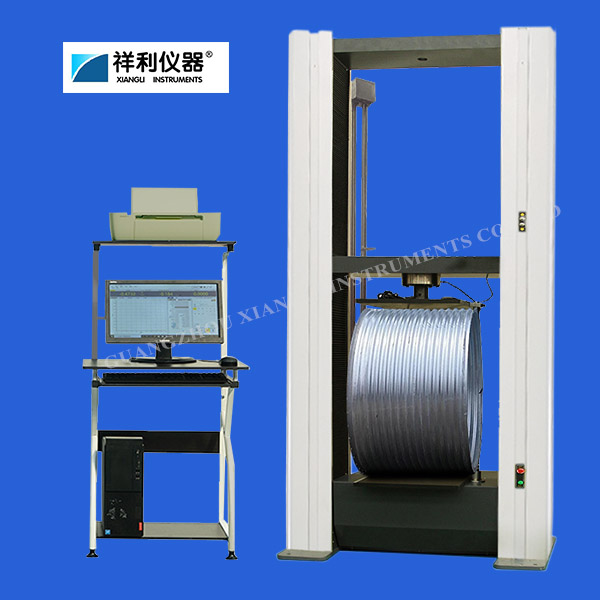

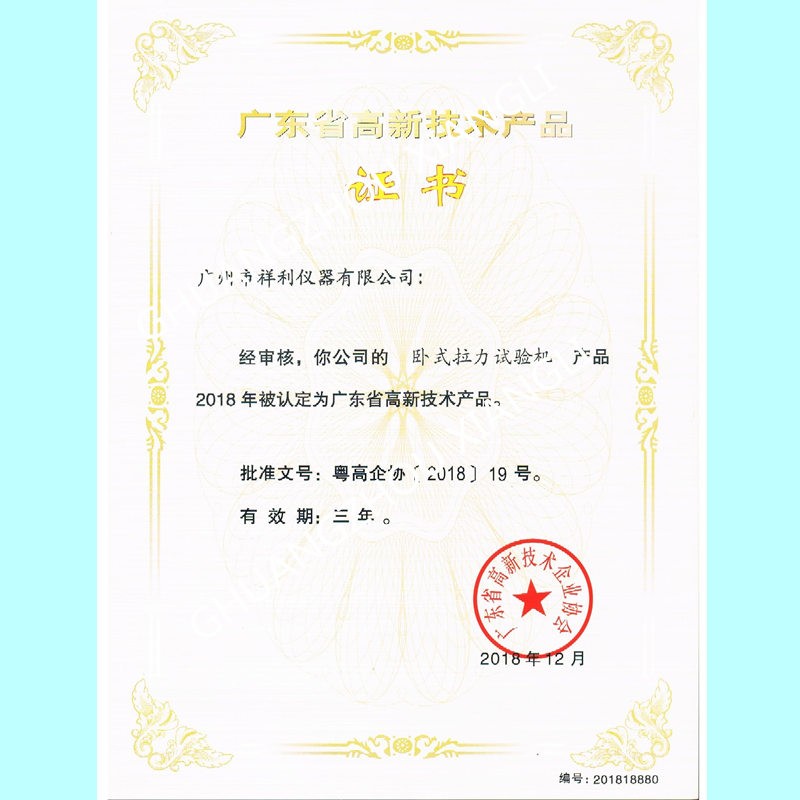

WXL-H50 Microcomputer controlled electronic ring stiffness testing machine

Brand :XIANGLI

Product origin :CHINA

Delivery time :25 days

Supply capacity :1000

WXL-H series microcomputer controlled ring stiffness testing machine adopts mechanical loading, electronic measurement, digital continuous speed regulation, and computer for real-time control.

The machine digitally displays test force, displacement/speed at the same time, and has a test force peak hold function.

It is suitable for testing plastic pipes' ring flexibility, ring stiffness, flatness, weld seam tension, pipe creep ratio, etc.

Working principle

★ Use the force value and deformation value measured when the pipe is deformed at a constant speed to determine the ring stiffness.

Place the pipe sample horizontally, determine the compression speed of the flat plate according to the diameter of the pipe, and

apply pressure to the sample in the vertical direction with two parallel flat plates.

★ A reaction force is generated during deformation,and the ring stiffness is calculated using the force value when the deformation in

the diameter direction of the pipe sample section is 0.03di.

Standard

Experiments can be conducted according to: GB, ASTM, DIN, ISO, JIS, BS and other standards.

1. GB/T 9647-2015 Determination of ring stiffness of thermoplastic pipes

2. GB/T 18477-2001 Rigid polyvinyl chloride double-wall corrugated pipes for underground drainage

3.GB/T 16800-2008 Core layer foamed rigid polyvinyl chloride pipes for drainage

4. GB/T1947 Buried polyethylene structural wall piping system

5. GB/T 165-2002 High-density polyethylene wound wall structural pipes

6. GB/T 838-1998 Glass fiber wound reinforced thermosetting resin sand-filled pressure pipe

7. Provisions of GB/T16491, GB/T5836 and other standards

For structural wall pipes with spiral ribs, corrugations or other regular structures (special instructions are required to determine the

span of the testing machine), the length of the specimen should be equal to (d i ± 20mm, but not less than 290mm, nor greater

than 1000mm)

Product specification

Host

It adopts a double-space portal structure, and the lower space is compressed and bent (the test space can be replaced according to user needs).

Mechanical process structure

The main frame mainly consists of a base, four columns and two screws to form a double-arm frame structure. The transmission

loading system uses an AC servo motor and a synchronous toothed belt reduction device to drive the high-precision ball screws

to rotate and then drive the moving beam to achieve loading. , the testing machine has good coaxiality, the upper, middle and

lower beams are made of cast steel, and the thickness of the cross beam reaches 200% insurance factor; it is beneficial to reduce

stress. The machine has beautiful appearance, good stability, high rigidity, high control accuracy and high work efficiency. Low

noise, energy saving and environmental protection.

Rack

★Strong self-lubricating guide rod increases the lateral rigidity of the equipment and ensures linear movement of the beam

★It can accurately align the cross joints, ensure coaxiality, and reduce differences in measurement data

★Key stress-bearing components are integrally made of cast steel to ensure the overall rigidity of the frame.

★Grind-grade preloaded ball screws and heavy-duty bearings ensure long-term zero-clearance operation of the equipment,

low noise, accurate test results, and good repeatability.

Product parameter

1. Maximum test force: 50kN;

2. Testing machine accuracy level 0.5

3. The test force is not divided into grades, and the measurement range is: 0.4%-100 FN;

4. Test force measurement accuracy: ≤±0.5%;

5. The repeatability error of test force measurement is better than ±0.5%;

6. Relative error of indication value: better than ±0.5%

7. Displacement speed control range: 0.01~500mm/min;

8. Displacement measurement accuracy: ≤±1%;

9. Displacement display accuracy: 0.001mm

10. Test space (upper and lower): 0~1600mm;

11. Test space width (left and right): 500mm;

For structural wall pipes with spiral ribs, corrugations or other regular structures (special instructions are required to determine the span of the testing machine), the length of the sample should be equal to (d i ± 20mm, But not less than 290mm, not more than 1000mm, this requires a testing machine with a span of 1.2 meters)

12. Power supply power: 750W, 220V, 50Hz.

13. Machine size and weight: about 900*550*2600 (mm), about 750KG

Features

1. Host appearance: Using spray oxidation process, the mold is formed in one step, which is beautiful and generous.

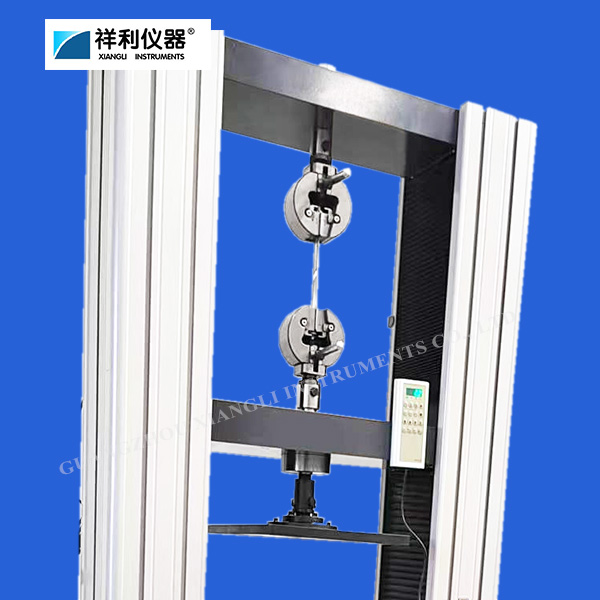

2. Force sensor: It adopts imported high-stability, high-precision strain gauge load sensor; the high-stability precision measurement

system ensures that the resolution remains unchanged throughout the process, ensuring that the maximum error of the test force

value does not exceed ±0.5%; it can be adjusted according to the Multiple load sensors are used in different ways to achieve

multi-range test force measurement; it has good temperature compensation, high sensitivity, high rigidity, and good long-term

stability.

★Compact design saves vertical testing space

★Safe load: 200% rated load

★Excellent linearity under tensile and compressive loads

★High longitudinal and transverse rigidity

★Load sensor from 0.4% of its capacity to full scale without loss of accuracy

★Load accuracy is 0.5% of the indicated load

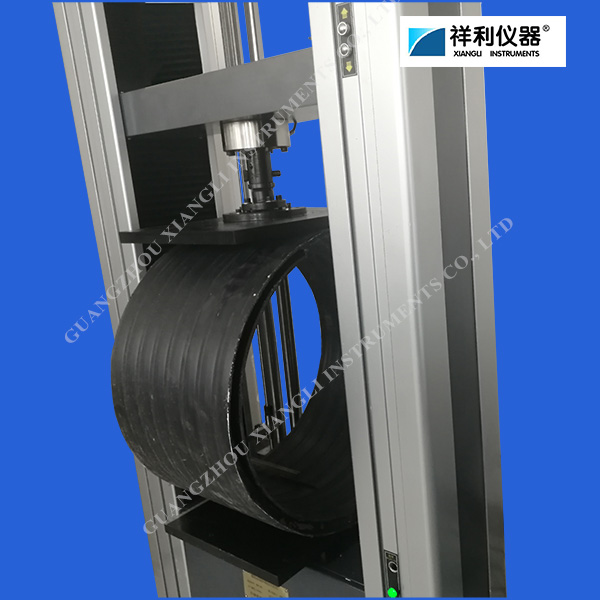

3. Internal deformation measurement system: The bilateral measurement internal deformation measurement system (a measurement system with wide deformation measurement range, high accuracy and fast response) that fully meets the requirements of national standards can achieve high-accuracy measurement of ring stiffness.

Internal deformation physical pictures

4. The motor adopts a domestic brand AC servo motor: it can achieve the industry's fastest response frequency of 2.0kHz, and the

reaction speed is fast; the beam moves smoothly and has no vibration when stopped, effectively shortening the high-precision

positioning time, and has low noise during operation. It is equipped with the latest controller. The controllable speed can achieve

the highest level of stable speed in the industry; the protection level reaches TP67 standard, and the environment is more adaptable.

5. Reduction system: Adopt synchronous belt transmission and deceleration, with low noise, smooth operation and high speed

control accuracy. The company is equipped with a special CNC gear hobbing machine to effectively ensure the accuracy and roughness

of the synchronous belt wheel teeth. The reduction ratio and synchronous belt tensioning method are accurately calculated and

reasonably designed to ensure the stable operation of the cross beam and the long-term good operating condition of the synchronous

belt.

6. High-performance sensor with high accuracy and long life. The exterior is made of stainless steel and has good waterproof

performance. The protection level can reach IP67.

7. Transmission system: A precision double-nut preloaded grinding screw with up to 72 processes is selected. The preload force is

accurately controlled to eliminate transmission gaps. Grinding ensures accuracy. The heat treatment process ensures the hardness

of the raceway. The screw transmission is stable and the noise is low. Long service life and lifetime maintenance-free.

8. Appearance: The host cover is made of aluminum alloy material extruded in one go. It has high hardness, good rigidity, and no

deformation. The surface is frosted, making the overall appearance beautiful and durable.

9. Control System:

★This machine adopts a built-in controller, which ensures that the testing machine can achieve closed-loop control of constant velocity displacement and constant velocity test force.

★Domestic brand AC servo motors have stable and reliable performance, and have protection devices such as overcurrent, overvoltage, overspeed, and overload. The speed regulation ratio can reach 1:100000.

★The electrical control circuit refers to international standards and complies with the national testing machine electrical standards. It has strong anti-interference ability, ensuring the stability of the controller and the accuracy of experimental data.

★Automatic shifting: Automatically switches to the appropriate range according to the load size to ensure the accuracy of measurement data; realizes automatic shifting, zeroing, and calibration of physical zeroing, gain adjustment, and test force measurement in the true sense and save to disk, without any analog adjustment links, and the control circuit is highly integrated.

★Condition storage: Test control data and sample conditions can be made into modules, which facilitates batch testing;

★Automatic speed change: The speed of the moving beam during the test can be changed automatically according to a preset program or manually;

★Automatic calibration: The system can automatically calibrate the accuracy of the indication value;

★Automatic saving: After the test is completed, the test data and curves are automatically saved;

★Process realization: The test process, measurement, display and analysis are all completed by microcomputer;

★Batch testing: For samples with the same parameters, they can be completed sequentially after one setting;

9. Software: The measurement and control software is used for microcomputer-controlled electronic universal testing machines to conduct various metal and non-metal (such as artificial boards, etc.) tests, and complete various functions such as real-time measurement and display, real-time control and data processing, result output and report printing in accordance with relevant standards.