- Home

- >

- Products

- >

- Universal Testing Machine

- >

- Electron testing machine

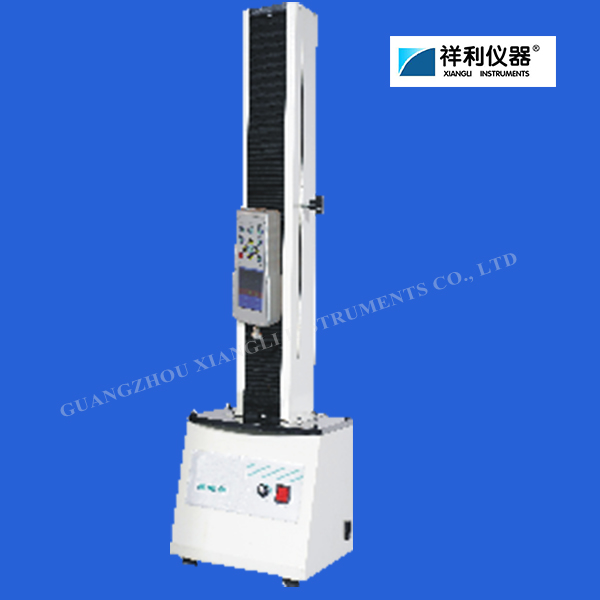

Electron testing machine

Brand :XIANGLI

Product origin :China

Delivery time :10 days

Supply capacity :1000

Electron testing machine equipped with push pull force gauge, has the advantages of stable, widely use and easily use.

Product specification

HC-LD Electric testing machine equipped with push pull force gauge, has the advantages of stable, widely use and easily use.

And it also has the functions of stepless speed control, manual, automatic, and time.

Work with the all kinds jigs, it applicable to push-pull test, insertion extract force test, destructive test.

Feature

● LED double figures with backlit display.

● USB data interface, support hot-plug.

● Set the max and min deviation, and free to select the alarm mode within limits and external limit.

● The screen can be 180°flipped.

● Three kind of units N、kgf、lbf can be free conversion, and also can bespoke other units such as gf、tonf、KN etc

● With peak keeping function, the peak automatically discharge and time discharge can be set freely.

● It can permanently store 10 groups test reports and automatically calculate our the peak, valley, average and etc in the test report.

● The power-saving functions shutdown automatically while no operation and automatically backlight.

● Use the specified software on the PC can store, deliver, review and print the test curve data.

● And it can combine with all kind of racks to achieve many kind of test.

Product parameter

| Type | HC-LD |

| Size | 370*250*980mm |

| Rate load | 0-100N,200N,500N,1KN,2KN |

| Test speed | When ≤1kN, speed 50-500mm/min When 1kN-2kN, speed 30-150mm/min |

| Max load | 600mm |

| Valid test height | 600mm |

| Weight | 32kg |

| Expand configuration | (When it loaded≤500N, can equipped with the built-in push pull force gauge) (When it loaded>500N, can equipped with the external push pull force gauge and force cell) |

Maintain

1. Open the machines everyday periodically.

2. Operated by the specialist.

3. Electron testing machine and accessories must be deposit in the dry environment.

4. After testing the accessories should be added wiping grease rust, and remove the rust great before test.

5. When the test finished, the power should be closed to avoid any accident.

Certificate