- Home

- >

- Products

- >

- Impact Testing Machine

- >

- Charpy impact testing equipments

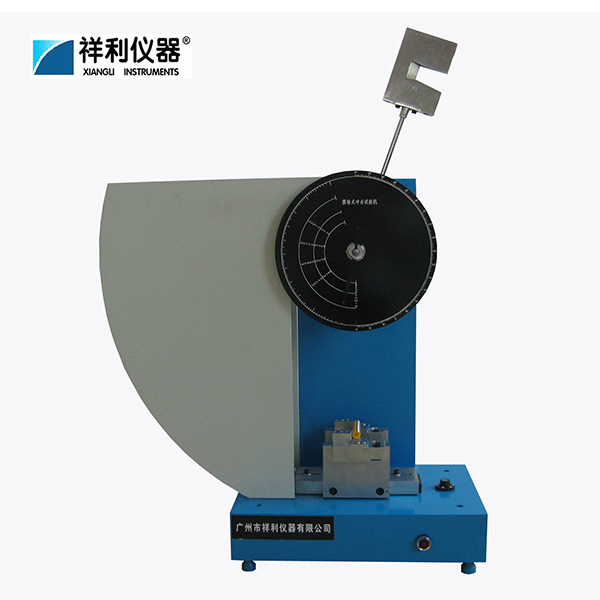

Charpy impact testing equipments

Brand :XIANGLI

Product origin :China

Delivery time :10 days

Supply capacity :1000

Charpy impact testing equipments accords with the standards ISO179 GB/T1043 GB/T2612 JB/8762 GB/4742.

Product parameter

|

|

XJJ-5 | XJJ-50 |

| Velocity at impact | 2.9m/s | 3.8m/s |

| Impact energy | 1J, 2J, 4J, 5J | 7.5J, 15J, 25J, 50J |

| Center distance of impact | 230mm | 395mm |

| Angle of elevation | 160° | |

| Radius of the pendulum | R=2±0.5mm | |

| Radius of the gag | R=1±0.1mm | |

| Included angle of impact | 30°±1° | |

| Span of the gag | 40mm,60mm,70mm | 60mm, 70mm, 95mm |

| Tester Dimension | 550×350×850mm | |

| Testing temperature | 15degree-35degree | |

| Power | AC220C 50Hz | |

| Tester weight | 160kg | |

Sample type

| Sample type | Length | Width | Thickness | Support distance |

| 1 | 80±2 | 10.0±0.5 | 4±0.2 | 60 |

| 2 | 50±1 | 6±0.2 | 4±0.2 | 40 |

| 3 | 120±2 | 15±0.5 | 10±0.5 | 70 |

| 4 | 125±2 | 13±0.5 | 13±0.5 | 95 |

Sample notch

| type A 45±1° | type B 45±1° |

| type C 2±0.1°right angle | type C 0.8±0.1°right angle |

Application

Charpy impact testing equipments is mainly used in measuring the tension impact-toughness resistance of the non-metal materials such as Hard plastic, glass, ceramics, nylon, electrical insulation materials and cast stone etc. This machine is a kind of simple structure, convenient operation, data accurate and reliable testing instruments. Charpy impact testing equipments applicable to GB/T1043, GB/T4742 provisions of the various sample impact test (including mechanical processing and molding gaps and no gap in the specimen), including four kinds of span 40 mm , 60 mm, 70 mm and 95 mm, when changing different clamps, then adjust seat can do all kinds of rope-grip impact test.

Charpy impact testing equipments accords with the standards ISO179 GB/T1043 GB/T2612 JB/8762 GB/4742.

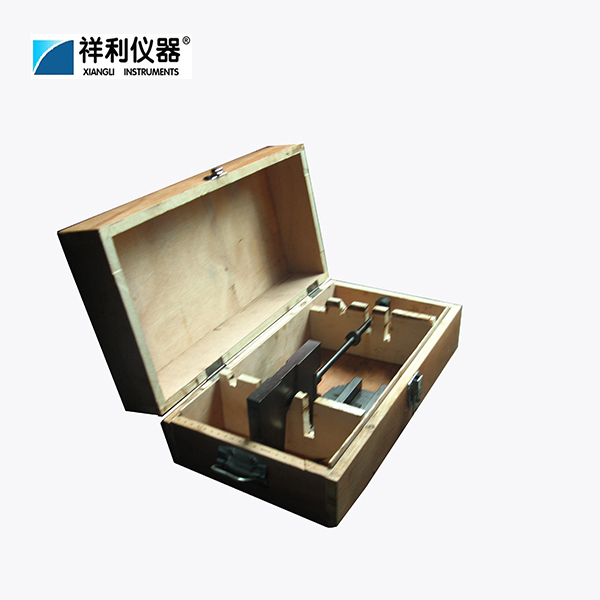

1. Open the machines everyday periodically.

2. Operated by the specialist.

3. Charpy impact testing equipments and accessories must be deposit in the dry environment.

4. After testing the accessories should be added wiping grease rust, and remove the rust great before test.

5. When the test finished, the power should be closed to avoid any accident.

Certificate