- Home

- >

- Products

- >

- Carbon black content tester

- >

- DZ3500S Carbon Black Content Tester

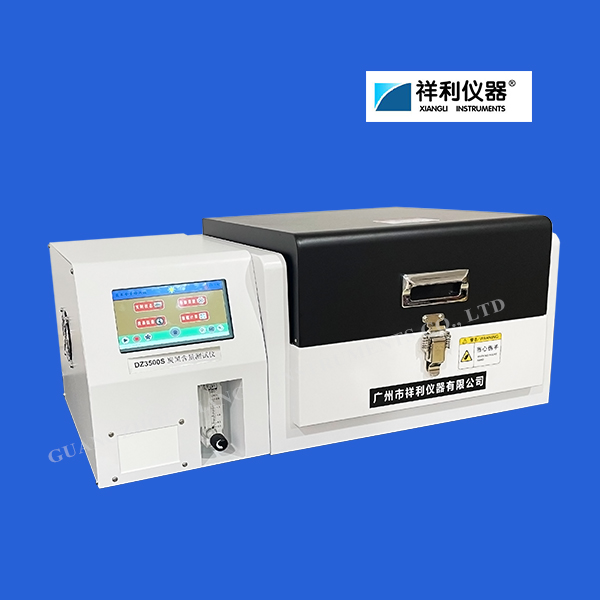

DZ3500S Carbon Black Content Tester

Brand :XIANGLI

Product origin :CHINA

Delivery time :7 days

Supply capacity :1000

The integrated design of the heating furnace body and control system facilitates user instrument management;

High degree of automation, just set the temperature value and heating time, and the instrument will automatically heat up to the set value;

High temperature control accuracy, wide temperature range, and high furnace temperature uniformity;

Product specification

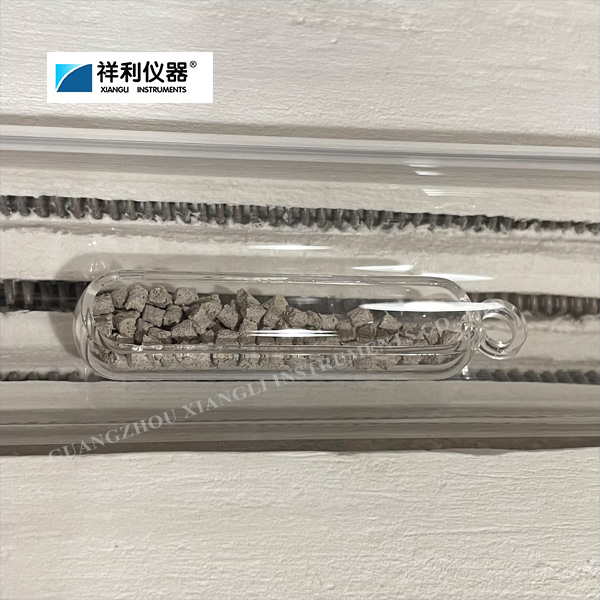

★ The carbon black content tester is suitable for the determination of carbon black content in polyethylene, polypropylene, polybutylene plastics, cable and optical cable insulation and sheath materials, and rubber.

★ Comply with national standards GBT 3515-2005, GBT 13021-1991, GB∕T2951.41-2008, IEC60811-4-1:2004, etc.

Working principle

★ A certain amount of sample is pyrolyzed at high temperature in a nitrogen flow, and the carbon black content is obtained by analyzing the weight of the sample after pyrolysis.

Product parameter

1. Display mode: 7-inch capacitive touch screen

2.Quartz tube size: φ44×600±5mm

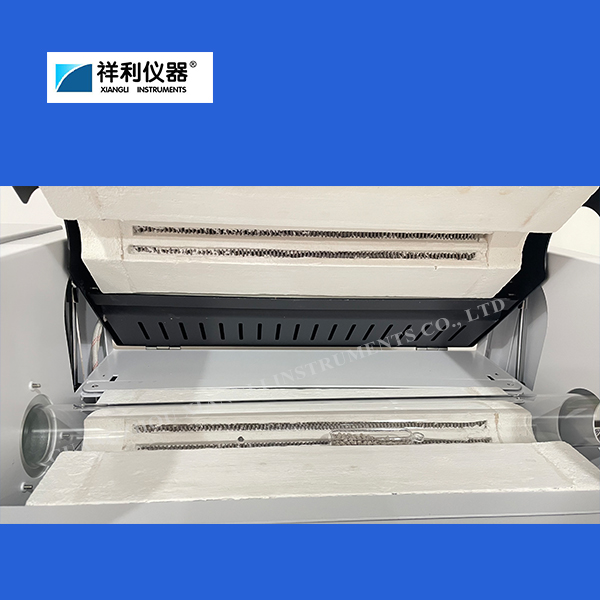

3. Furnace size: Φ45×300±5mm

4. Heating element: high temperature alloy wire

5. Heating zone length: 300mm

6. Working temperature: room temperature -1200℃

7. Temperature control method: Intelligent programmable control, segmented programs can be set.

8. Working power supply: AC220V/50HZ/60HZ

9. Sensor sensitivity: 0.1℃

10. Air circuit control: two circuits, automatic program switching

11. Cooling method: rapid cooling (≤20min, 900℃ to room temperature)

12. Number of test samples: test 4 samples at a time, increasing the efficiency by 4 times

13. Data calculation: The software has its own calculation function, one-click calculation; it can automatically calculate the carbon black content and ash content.

14. Customized rail-type sample rack, convenient for taking and placing samples.

15. Open cover type, rapid cooling, reducing test cooling time.

16.With exhaust gas filtering device

17. The instrument has a printing function, and the test results can be printed directly.

Features

1. The instrument has beautiful appearance and structure and is easy to operate;

2. The integrated design of the heating furnace body and control system facilitates user instrument management;

3. High degree of automation, just set the temperature value and heating time, and the instrument will automatically heat up to the set value;

4. High temperature control accuracy, wide temperature range, and high furnace temperature uniformity;

5.7-inch LCD touch screen display, extremely friendly operation interface, can be started with one button operation;

6. It has excellent constant temperature function and can set the constant temperature time with high constant temperature accuracy;

7. The instrument can set any group of different heating time periods, and can have different heating temperatures, heating rates, and constant temperature times;

8. Comprehensive parameter display, showing the set number of groups, theoretical temperature, actual temperature, and heating time (or constant temperature time);

9. During the operation of the instrument, the set parameters and heating or constant temperature time can be viewed;

Maintain

1. Open the machines everyday periodically.

2. Operated by the specialist.

3. The equipment and accessories must be deposit in the dry environment.

4. After testing the accessories should be added wiping grease rust, and remove the rust great before test.

5. When the test finished, the power should be closed to avoid any accident.

Certificate